Heavy Duty Pallet Racks

Heavy Duty Pallet Racks - Conventional Pallet Racks

We are leading Manufacturer, Supplier, Exporter of Heavy Duty Pallet Racks - Conventional Pallet Racks from Pune, Maharashtra, India.

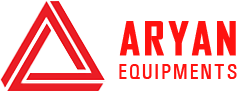

Conventional Pallet Racking Systems generally store parallelized products in warehouses with a wide range of load types. This is the most convenient system of racking is goods can easily be removed as each pallet can be accessed without the need to shift the other pallet. Another advantage of the system is total stock control; each storage space is taken up by a single pallet, also maximum adaptability to any load type both in terms of weight and volume.

The conventional pallet racking in warehouse is generally laid out with single-entry wall racks on the perimeter sides and double-entry racks in the middle. The working aisle measurement between each rack and the rack height depends upon the characteristics of the fork-lift trucks or lifting devices, pallet size and the height of the warehouse itself.

In order to store a greater number of pallets, depending on their weight and the number of pallets per load type, double-deep racks can be installed enabling one pallet to be stored in front of another on each side of the aisle. Direct access can only be made to the front pallets and so it is only recommended to store products with several pallets per load type so as to avoid an increase in maneuver times due to double movements. This system requires suitable lifting machinery fitted with double-depth telescopic forks.

Long Span Racks

Available in wide range of sizes and duties

- Easily configured to meet your load volume, weight and handling requirements

- Adjustable beam levels for varying pallet heights

- Aisles designed for counter balance or reach truck operations

Benefits

- Offers easy accessibility to pallets

- Easily manages non-uniform loads

- Easily installed whilst its versatility makes it a cost effective solution

- Does not require specialist truck training

Double Deep Pallet Racks

In this type of Racking, 2 Pallets are operated at same time with an extra attachment on MHE, Front Pallet taken out and then the rear pallet is used

Narrow Aisle Pallet Racks

This Aisle space used to such Racking is very labs and is economical to high rise Storage System.

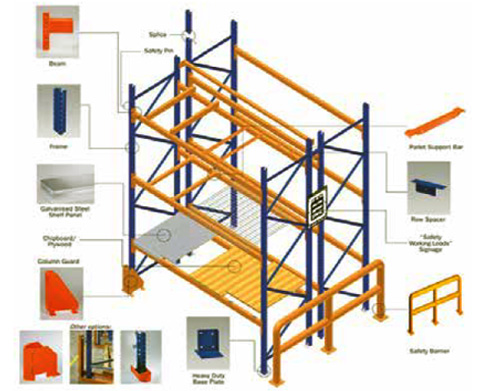

Drive in Pallet Racks

This type of storage is chosen for pressure sensitive goods or unstable storage units which are stored in big qantity.

General Advantages :

- Compact Storage according to the First In - Last Out principle.

- High Volume utilization due to compact storage.

- Save floor space.

- very economic pallet storage systems.

Medium Duty Storage Rack

Facilitates Storage of non palletized items. Ideal for Medium to large sized items that can be handled Mnually.

General Advantages :

- Loading levels can be customised based on height of the SKU stored.

- Integration possible with suitable material handeling equipment for moving material to various levels.

- Goods Liifts can be added on custom fabricated staricases provided for ease of use.